Diamond Wire

Diamond wire, also known as diamond cutting wire (briefed in diamond wire), is a kind of linear cutting tool formed by consolidating diamond abrasive onto steel wire substrate using adhesive. It can be divided into resin diamond wire and electroplated diamond wire by the type of adhesive and preparation method. Electroplated diamond wire is a kind of cutting wire formed by solidifying diamond onto steel wire substrate via electroplating nickel.

Electroplated diamond wire is mainly used for cutting of hard and brittle materials, including cutting, squaring, and slicing of monocrystalline silicon and polysilicon in the photovoltaic field, cutting and slicing of semiconductor materials, cutting of nonmetal hard and brittle materials such as sapphire, special glass, ceramics in the LED field, and cutting of magnetic materials such as neodymium-jron-boron and ferrite.

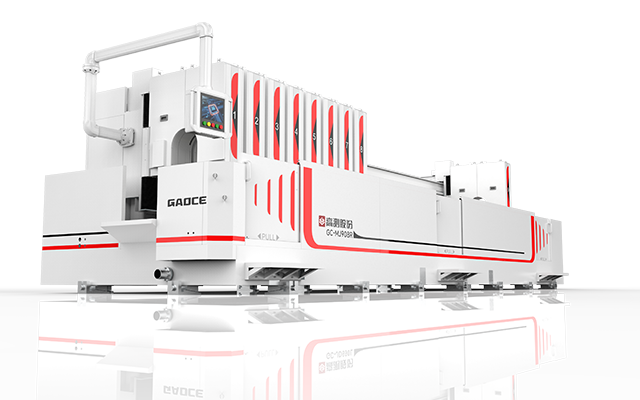

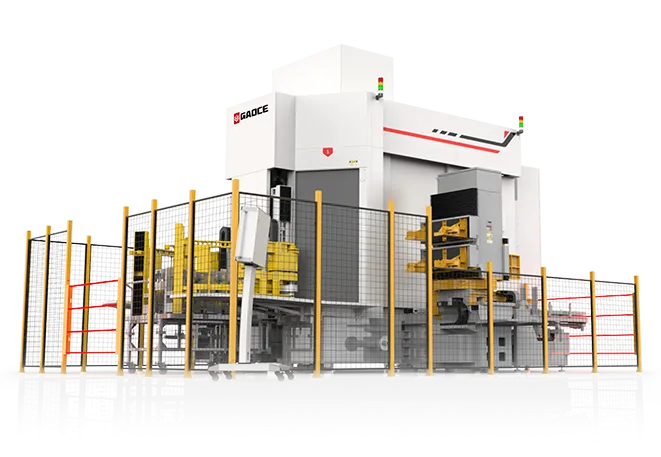

Based on in-depth market insights and a relatively perfect R&D system, Gaoce Inc. gives full play to the advantages of collaborative R&D and technological closed-loop of“cutting equipment, cutting processes, and cutting consumables”, and continues to promote the unending improvement of diamond wire manufacturing technology and product performance.

Thinning development: the Company has always led the industry to promote the thinning iteration R&D and testing of the tungsten wire and carbon wire, and continuously reduces the cutting costs.

Product performance: with continuous process optimization and equipment upgrading, all specifications of products have good cutting ability, which greatly improves the uniformity of micro powder distribution and blade consistency, so as to ensure that the customers can control the amount of cutting wire, cutting wire breakage and sheet surface quality, and sheet thickness uniformity.

Cost competitiveness: the company has always been committed to cost reduction driven by technological innovation, helping the industry reduce costs and increase efficiency.

Product Parameters

Specifications |

Wire Diameter /μm |

Cutting edge rate |

Breaking load /N |

Purpose |

28 Electroplated diamond wire (tungsten wire) |

46±2 |

90±30 |

≥6.0 |

Monocrystal cutting |

30 Electroplated diamond wire (tungsten wire) |

48±2 |

90±30 |

≥6.2 |

Monocrystal cutting

|

30 Electroplated diamond wire (high-carbon steel wire) |

47±2 |

80±30 |

≥5.5 |

Monocrystal cutting

|

32 Electroplated diamond wire (high-carbon steel wire) |

49±2 |

90±30 |

≥5.8 |

Monocrystal cutting

|

34 Electroplated diamond wire (high-carbon steel wire) |

51±2 |

100±30 |

≥6.0 |

Monocrystal cutting

|

0.32 Electroplated diamond wire |

320±20 |

50±10 |

≥160 |

Crystal silicon cutting |

0.37 Electroplated diamond wire |

370±20 |

65±10 |

≥200 |

Crystal silicon cutting |

0.42 Electroplated diamond wire |

450±20 |

70±10 |

≥270 |

Crystal silicon cutting |

Related Products

Relevant Cases

Sustainable Development

Related Solutions

Get Quote

Fill in a brief message and we will contact you as soon as possible~