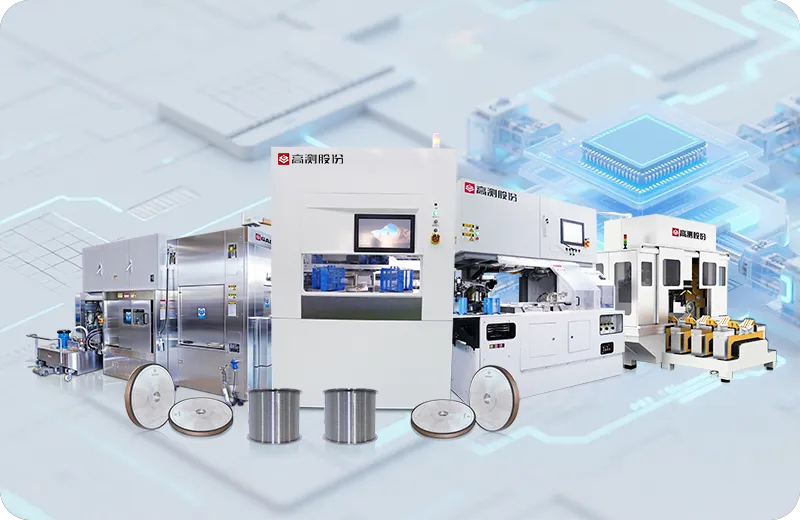

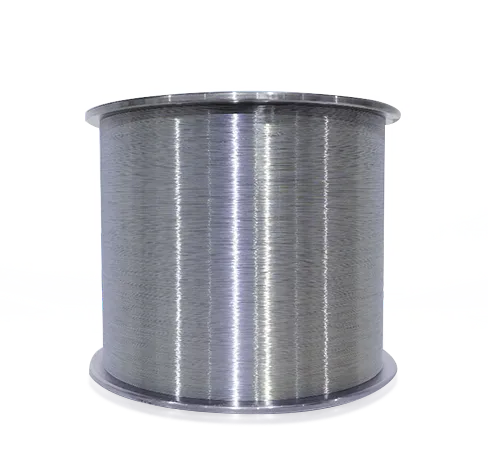

Powered by its platform-based technology engine, Gaoce enables cross-disciplinary technology transfer by applying its precision cutting and precision grinding platform technologies to semiconductor silicon material processing, offering an integrated “cutting–chamfering–grinding” solution. Leveraging self-developed and self-manufactured equipment and consumables, along with a global service network, Gaoce provides customers worldwide with a full range of value-added services, including comprehensive lifecycle technical support, integrated control, on-site commissioning, operator training, and after-sales service, ensuring smooth and worry-free production. Currently, the 8″ semiconductor diamond wire slicing machine has been successfully exported to Europe; the 12″ semiconductor diamond wire slicing machine is under trial use by leading domestic customers. The 4–8″ semiconductor chamfering machines have been delivered to top domestic customers and received positive feedback, while the 12″ chamfering machine prototype has been successfully developed and is ready for market launch. Meanwhile, Gaoce has developed dedicated diamond wires and chamfering grinding wheels for semiconductor silicon processing and has established long-term stable cooperation with leading industry clients.