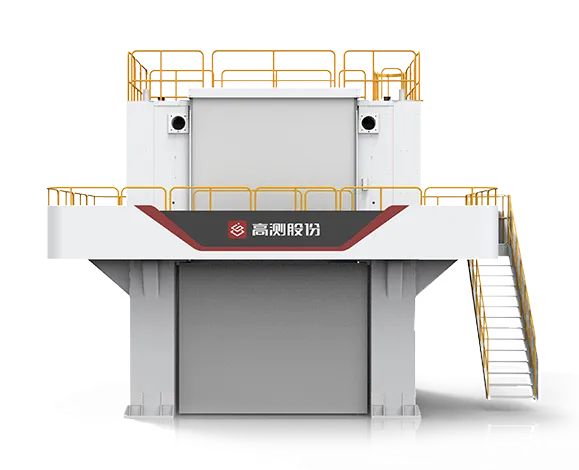

GC-SQ3423Stone Thin Multi-wire Saw

This equipment is a special equipment of using the diamond wire to cut the marble, granite and other rough stone blocks into wafers, which was launched in 2024.The equipment adopts feeding method by stone lifting up. We have custom-developed diamond wire for stone cutting industry. Relying on the technical closed-loop advantage of "equipment + tools + process", the Stone wire saw greatly reduces the pain spots of traditional gang saw cutting such as low yield, high energy consumption, loud noise, dust pollution and so on. It helps the stone processing factory to achieve clean production and green development with high yield, low noise, good cutting surface quality, high cutting preci- sion, good equipment stability, greatly reduces powder discharge, more environmentally friendly.

1. Stable and reliable: The cast frame of equipment is shock-absorbing and wear-resistant. It allows for long-term stable cutting with mature photovoltaic technology.

2. Technical closed-loop advantages: Dive in and Focus on the cutting process, cutting tools, and cutting equipment. Provide an integrated solution for the stone cutting industry and Form a technical closed-loop advantage to create value for users continuously.

3. Good cutting flatness: High feed accuracy from stable equipment frame, strong cutting force, stable wire mesh control and highly process matching contribute to better cutting flatness.

4. Low processing cost: High cutting efficiency by improving the line speed, tension and feed speed continuously. Less wire consumption through R&D special stone diamond wire. Dedicated to cost down for customer.

5. Excellent service: We have professional service team with more than 15 years of diamond wire cutting experience that can provide customers with one-stop services. Response within 24 hours.

6. High compatibility: The design considers the future technology development trend, reserve the upgrade iteration interface, easy to update.

Product Parameters

Category |

Items |

GC-SQ3423 Parameter |

Basic Parameter |

Block Entry into Machine |

Front/Side |

Feeding Mode |

Trolley Movement |

|

Processing BLOCK Size |

Max.3400x2300x2200mm (ODM Available) |

|

Machine size (LXWXH) |

8600x6100x7000mm (ODM Available) |

|

Roller Spec (ODXL) |

Iron (φ275-φ305)x2320mm |

|

Operation Speed MAX |

1800m/min |

|

Cutting Thickness |

5-30mm |

|

Wire Diameter |

0.45-0.65mm |

|

Wire Storage (0.55) |

30km |

|

Operation Tension MAX |

230N |

|

Total Power |

300KW |

|

Control System |

Siemens/Delta/ inovance |

|

Weight |

55t |

|

Processing Capability |

Expected Production |

8000-14000 ㎡/month (for 18mm thickness) |

Type of Material |

Hard/Medium/Soft Marble |

|

Qty of Trollies Per Month |

30-35 trollies |

|

Sawing Cost/㎡ |

USD0.8-USD1.40/㎡ |

|

Standard Fittings |

Electroplated Wire |

φ0.55mm Qty:30km |

Wiring tool |

1 pcs |

|

White Wheel |

50 pcs |

|

Rollers |

4 rollers |

|

Drums |

2 pcs |

|

Optional Fittings |

Iron Roller |

□φ305-φ340 |

Aerospace Aluminum |

□φ315-φ350 |

|

Energy Save Function |

□As requested |

|

Power Lost Protect |

□As requested(Wire no break once power lost) |

|

Remote Maintenance Function |

□As requested |

|

Wire Bow Control Alarm |

□As requested |

|

Trolly |

□to be bought separately or at market price |

|

Grooving Machine |

□to be bought separately or at market price |

|

Wire transfer Machine |

□to be bought separately or at market price |

Related Products

Sustainable Development

Related Solutions

Get Quote

Fill in a brief message and we will contact you as soon as possible~