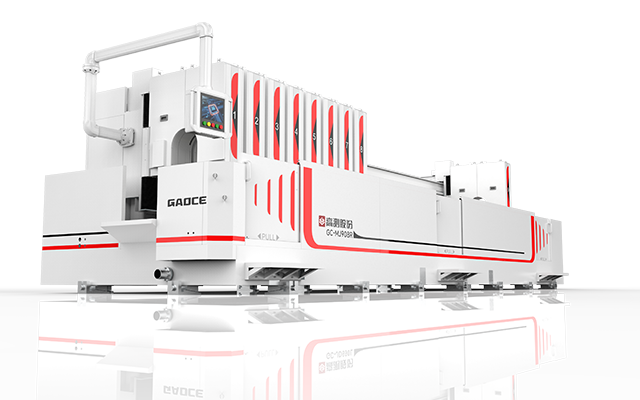

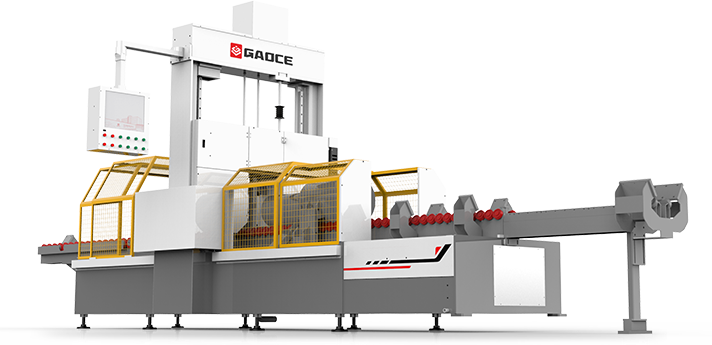

Gaoce is a wafer slicing service provider with the world's leading large-scale production capacity and comprehensive compatibility across various wafer specifications. Since 2021, Gaoce has leveraged its complete technical ecosystem by integrating cutting equipment, cutting consumables, and cutting processes to provide wafer cutting and processing services to global customers, offering wafers in multiple specifications. As of June 30, 2025, the company’s total planned production capacity has reached 102 GW, with 63 GW in operation, distributed across Yibin and Leshan in Sichuan Province and Yancheng in Jiangsu Province. Its cumulative wafer output has exceeded 100 GW.

The company continues to enhance its level of intelligent manufacturing by deeply integrating cutting-edge technologies, such as the Industrial Internet, Big Data, Digital Twin, and Generative Artificial Intelligence, into wafer manufacturing scenarios. It is committed to building technologically advanced, highly intelligent, and cost-efficient wafer production bases. Through the combination of technological and cost advantages, the company supports global wafer manufacturers to reduce costs and improve production efficiency.